Section 5: Liquid Fertilization, Controlled-release, and Slow-Release Fertilizers

Mineral nutrients may be supplied to greenhouse crops through a liquid fertilization program (water soluble), a controlled release fertilizer, or a slow-release fertilizer. Each of this methods of fertilization has benefits and limitations for greenhouse crops production.

Liquid Fertilization with Water-Soluble Fertilizers

Liquid fertilization is most common with greenhouse crops. It provides the highest degree of flexibility and control of a crop’s nutrition, and formulations may be designed to match various water quality and crop scenarios. With liquid fertilization using a water-soluble fertilizer, the composition, concentration and frequency of nutrient delivery can be readily changed as needed. Furthermore, liquid fertilization can be used to help correct pH and E.C. problems that may occur during production.

Water-soluble fertilizers are designed to be injected into irrigation lines or systems. The fertilizer salts used to make these fertilizers are higher quality than those commonly used in turf and field agriculture applications. The higher quality fertilizer salts increase the solubility, decrease turbidity and reduce contaminants. The use of chelated micronutrients in liquid fertilization also enhances solubility and availability for uptake.

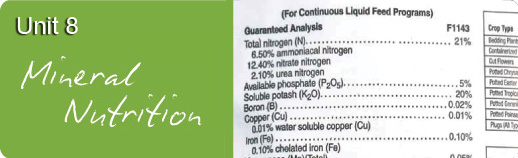

Premixed commercial water-soluble fertilizers are marketed under different brand names and are available in numerous formulations (i.e. 20-10-20, 15-5-15, 15-0-15, etc.). These fertilizers are actually a mixture of various fertilizer salts (i.e. KNO3, NH4NO3), chelated elements (i.e. Fe-EDTA, etc.) or other water-soluble nutrient sources (i.e. boric acid) blended together to form a fertilizer with the ratio of mineral nutrients listed on the label. Many commercially prepared water-soluble fertilizers contain a dye that allows visual verification that fertilizer is being injected into the fertilization line. However, this dye should not be used to monitor the suitability or strength of the fertilizer solution. This should be done using an E.C. meter (see checking injector function later in this learning unit).

Although premixed commercial water-soluble fertilizers are an easy way to provide mineral nutrients in a liquid fertilization program, some greenhouse managers may choose to prepare their own water-soluble fertilizers using individual mineral salts [i.e. Ca(NO3)2, KNO3]. In this case, the greenhouse manager selects various fertilizer sources and mixes them at ratios designed to provide the mineral nutrients at the desired concentrations and ratios.

Liquid fertilization may be conducted as once per week applications (“periodic feed”) or as frequently as with each irrigation (“constant liquid feed”). However, rates must be adjusted accordingly and the more frequently the mineral nutrients are provided, the lower the concentration that is used. Keep in mind that if using a periodic feed versus a constant liquid feed program, when clear-water irrigation (water without fertilizer) is used in between fertilization cycles, mineral nutrients in the substrate may be leached if too high of a volume of clear water is applied. Thus, the efficiency of the nutrient delivery may be drastically reduced unless no leach or low leach irrigation is practiced.

Also, a constant liquid fertilization program is often preferred to a periodic feed program. This is because when a high concentration of fertilizer is applied, the concentration of nutrients may exceed the optimal concentration (and E.C. level may exceed optimal). Over time, the levels drop into the optimal range. With more time, levels continue to drop and if enough time occurs between fertilizations, the mineral nutrient levels may drop to below optimal before fertilization is repeated. With a constant liquid fertilization program, the nutrients may more precisely be maintained within an optimal range for the crop.

When mixing fertilizer salts, one must consider that some salts are incompatible with one another especially in high concentrations. In liquid fertilization systems it is not uncommon for two separate concentrate stock tanks to be used. In the first tank, the salts containing Ca and K are dissolved. In the second tank phosphate salts, sulfate salts and micronutrients are dissolved (keep concentrated sulfates and phosphates away from calcium). This practice helps to insure that precipitates do not occur in the stock tanks. Precipitates are generally insoluble, can clog injectors and are unavailable for uptake by the plant.

The two fertilizer concentrates are injected separately into the irrigation line where they are diluted and mixed and the concentration is typically not high enough for significant precipitation to occur. Common precipitates that can occur include CaSO4 and CaPO4. These precipitates form more readily under high pH, so many greenhouse managers will acidify the concentrate stock tank water to further help prevent precipitates from forming.

Greenhouse managers who are not using a two-stock tank system must still consider the issue of fertilizer salt compatibility. For instance if a grower is using sulfuric acid (H2SO4) injection to reduce the amount of alkalinity in the water, the sulfuric acid may provide significant SO4- which can combine with Ca in the fertilizer to form CaSO4 which can precipitate out of solution. A similar problem can occur when using a fertilizer with significant amounts of Ca and Epsom salts are added. Again, insoluble CaSO4 can be formed. One way to avoid some of these problems is to use chelated forms of cations. This strategy along with acids are commonly used in premixed water soluble fertilizers.

Fertilization with Controlled-Release Fertilizers

Controlled-release fertilizers are marketed under several brand names (i.e. Florakote®, Multicote®, Nutricote® , and Osmocote®) and are available in numerous formulations. Controlled-release fertilizers are designed to slowly release the nutrients that they contain into the substrate for uptake by the crop. Controlled-release fertilizers are produced by encapsulating water-soluble fertilizer salts in a polymer or resin (forming small round prills) that allows water vapor to enter and the fertilizer salts to slowly diffuse into the surrounding substrate solution (for polymer-coated) or the capsule may absorb water and swell to the point of bursting (for resin-coated). Increasing the thickness of a polymer coating increases longevity (release time) of the fertilizer by slowing the diffusion rate of the nutrients from within the prill. Increasing the thickness of the resin results in increased resistance to bursting; thus, delaying the release of fertilizer salts and increasing longevity.

With both types of coatings, varying the thickness of the coatings helps to provide a predictable release pattern of the nutrients from the prills that is dependent upon temperature. Therefore, controlled-release fertilizer labels will indicate the release period (i.e. 60-day, 6 to 8 months, 100-day, or 12 months, etc.) in addition to the guaranteed analysis (i.e. 15-7-15) and the recommended application rates for various crops and container sizes. The key to the rate of release is the temperature. The ratings by most fertilizer manufacturers are based upon 70°F (21°C). So a typical “5 to 6 month” controlled-release fertilizer would last up to 6 months if the temperature of the substrate is a constant 70°F. If the temperature is increased to 90°F, that same fertilizer might only last for 3 to 4 months. Because of the gradual release of mineral nutrients, controlled-release fertilizers typically do not significantly affect the substrate pH to the same degree that water-soluble fertilizers can.

Controlled-release fertilizers may be top-dressed onto the surface of the substrate or incorporated into the substrate. Placement of the fertilizer prills may have an effect on fertilizer efficiency depending upon the irrigation method used. If using an overhead irrigation system, the prills may be either incorporated or top-dressed. The flow of water through the substrate at irrigation will move mineral nutrients released from the prill through the substrate. However, if subirrigation is being used, prills should be incorporated into the substrate. This is because if prills are top-dressed and subirrigation is used, the mineral nutrients will not be able to readily move down into the substrates where most of the roots will be located.

In some situations, a grower might incorporate a controlled-release fertilizer into the substrate at a low rate (i.e. half the recommended rate) and supply the remaining fertility requirement through a liquid fertilization program. This provides increased flexibility since once a controlled-release fertilizer is incorporated into a substrate it can't be removed and excess nutrients can't be easily leached out. This tactic can also facilitate feeding crops with various nutrient requirements through single liquid fertilizer injection system.

Fertilization with Slow-Release Fertilizers

Slow–release fertilizers are not as common in general fertilization for greenhouse crop production as they are in turf or field agriculture. Slow-release fertilizers are generally differentiated from controlled-release as they aren’t coated with a resin or polymer. The mechanism that controls the nutrient release can be microbial degradation, hydrolysis, or a combination.

Probably the most common slow-release fertilizer used in greenhouse crop production is methylene urea or urea formaldehyde. These are commonly used in bark-based substrates as a measure to prevent nitrogen drawdown due to the continuing break down of bark from the composting process. There are several different manufacturers of methylene urea and its breakdown and subsequent nitrogen release is controlled by microbial degradation. However, different manufacturers formulate the products slightly different (more or less carbon in the chain) resulting in quicker or slower nitrogen release. A similar product is isobutyldiene diurea (IBDU). Breakdown of this product is controlled by hydrolysis. Other products that may fall into the category of slow-release fertilizers include metal-oxides (slowly soluble, pH dependent), sulfur-coated fertilizers (microbial degradation release) and sucrates (slowly water soluble).