Section 8: Nutritional Management and Monitoring

Fertility management is one of the most challenging aspects of greenhouse crops production. Many factors impact the nutritional status of a crop and should be considered when developing a fertilization program, monitoring the mineral nutrition status of a crop and making adjustments to the fertilization program. Among the factors that should be understood and considered are crop stage, time of year, amount and ratios of mineral elements, form of mineral elements, substrate and substrate components being used, substrate pH, substrate cation-exchange-capacity, substrate electrical conductivity, water quality and irrigation method.

Crop Stage

Newly planted cuttings, young seedlings and plugs require a lower mineral nutrition (fertility) level than actively growing crops. Typically, younger plant materials are grown at lower fertility levels and as the root system develops and the plants start to grow rapidly, fertility is increased. As plants enter into the reproductive stage (flowering), the nutritional requirements decrease compared to the active vegetative growth stage and the concentration of fertilizer provided may be decreased.

Though some greenhouse managers withhold fertilizer from young seedlings and cuttings, it has been demonstrated by researchers that there are benefits to providing mineral nutrients at optimal levels at all stages of plant development.

Time of Year

Under warm temperatures and high light levels, plants grow more rapidly and utilize mineral nutrients at a faster rate. As temperatures and light increase, the fertility level may need to be increased to meet the crop's increased demand for mineral nutrients. Under the cooler temperatures and lower light conditions of winter months, fertilization may need to be reduced.

As discussed earlier, nitrogen can be supplied to the crop in various forms. The NH4+ form can be converted to NO3- in the substrate by microorganisms. One caveat of NH4+ is that a small amount readily converts to ammonia (NH3), which is toxic to plants in very low concentrations. When substrate temperatures are low as they will be in a greenhouse during the winter months (even when heated), microorganisms are less active and the conversion of NH4+ to NO3-is slower. Under these conditions, NH4+ can accumulate in the substrate and more NH4+ is converted to NH3 and it can build up to toxic levels. High levels of NH4+ in the substrate can also inhibit the uptake of Ca++ deficiency in the crop. Therefore, changing the form of nitrogen supplied to the crop during late fall, winter and early spring can be beneficial in preventing NH3 build-up in the substrate and greenhouse managers thus limit the use of NH4+ nitrogen sources (applying more NO3- based nitrogen sources instead) during winter months (especially in northern latitudes).

Amount of Mineral Elements

Mineral nutrients may be present at concentrations that are deficient (below the level the plant needs for optimum growth and development), concentrations that are in excess (above the level the plant can use), concentrations that are phytotoxic (concentrations at which some type of physiological damage is done to the plant) or at concentrations that interfere with (antagonize) the uptake of other mineral elements (high Mg++ can inhibit the uptake of Ca++). The objective in a fertilization program is to maintain each element within an optimal range throughout the crop cycle. The optimal concentration for any given mineral nutrient may be different for different crops and different growth stages of the crop.

When using a granular fertilizer (not the high grade or fast dissolving water soluble fertilizers) such as superphosphate to supply phosphorus or dolomitic limestone to provide calcium and magnesium, these minerals break down or dissociate slowly in the substrate and release the desired mineral nutrients over time. However, very early in the crop cycle the desired mineral nutrient may be below the optimal level until enough is released into the substrate solution to increase the level of the mineral nutrient into the optimal range. The level of the desired mineral nutrients may then be within the optimal range for many weeks. However, over time, the level may drop and fall to concentrations below optimal especially for long-term crops.

Fertilizer salts that are readily soluble [i.e. calcium nitrate [Ca(NO3)2], potassium nitrate (KNO3), or magnesium sulfate (MgSO4), etc.] result in a more rapid increase in the level of the mineral nutrients they supply, but the level may also drop more quickly unless additional sources are provided.

Controlled-release fertilizers are designed to allow the fertilizer salts held within a coating to slowly dissolve and diffuse or leach into the substrate. This allows for a more constant supply of the mineral nutrients and allows them to be maintained within an optimal range over a specified period of time. However, even with the use of controlled-release fertilizers, there is a period of time required for the fertilizer salts to enter into the substrate and increase the levels of mineral nutrients to the optimal ranges. Additionally, over time the level of mineral nutrients leaching from the controlled-release fertilizer will decrease and the level of mineral elements in the substrate may drop below optimal levels.

When using periodic liquid fertilization, (typically 300 - 500 ppm N per fertilization with fertilization being once per week or less), the levels of the applied nutrients increase rapidly and may even reach levels that are above optimal depending upon fertilizer concentration and crop. In between fertilization cycles, the level of mineral nutrients decreases as the plants take them up (or they are leached out). Between fertilizations, the level might stay within the optimal range or might drop below optimal levels depending upon the concentration of the fertilizer solution used, the time interval and amount of clear water irrigations used between fertilizations, leaching fractions and the rate of crop growth.

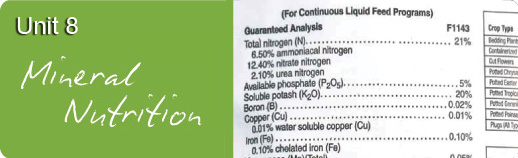

Constant liquid fertilization (CLF) is a practice in which the concentration of the fertilizer solution is reduced (i.e. typically 75 – 250 ppm N) but is applied with each irrigation. Constant liquid fertilization allows for a more consistent fertility level to be maintained. However, the fertility concentrations may need to be altered depending on plant development stage and other environmental factors.

Often, especially where a liquid fertilization program is to be used, several fertilization cycles may be required to bring the mineral nutrient content of the substrate up to the desired concentrations. During this period, the mineral nutrient levels may be below optimal and may be limiting to plant growth. For this reason, the substrate may be amended with what is referred to as a nutrient starter charge. The nutrient starter charge is typically some type of fertilizer salt that is rapidly available but incorporated at a low concentration and is designed to last only a few irrigations. Essentially, this is a “booster” to provide nutrients to the crop at planting until the liquid fertilization program can begin to effectively provide the required mineral nutrients. Nutrient starter charge fertilizers may be typically Ca(NO3)2, KNO3 or NH4NO3 or complete fertilizers that contain all macro- and micronutrients.

Proportions/Ratios of Elements

Not only are the absolute amounts of mineral elements provided important, but the ratios of the mineral elements to one another are important. Problems can occur if mineral nutrients are out of balance. Excess P (in relation to N and K) can cause stem elongation of annual bedding plant species. Excess levels of certain elements can cause antagonisms of other mineral elements because of competitive uptake. For example, excess K or excess NH4+ can cause Ca deficiency.

The ratio of K to Ca is important. A good estimate is to apply nearly twice the amount of K as is provided of Ca. Also, Mg is typically provided at about 50% of the concentration as Ca resulting in a 4:2:1 ratio of K:Ca:Mg.

Microelements are provided at much lower concentrations than the primary and secondary macroelements. The exact chemistries of nutrient uptake and exchange are hard to summarize when evaluating substrate nutrient ranges, but some basic rules are commonly followed for micronutrient application ratios. For example, iron is often formulated at 0.075 to 0.1 % concentrations for a 20% nitrogen water-soluble fertilizer that is designed to be used in a peat-based substrate. Manganese is generally supplied at 50% the concentration of Fe and Cu and B at 30% to 40% of the Mn.

These generally recommended ratios of the mineral nutrients to one another do not always apply to all crops. There are many exceptions. For example, carnation develops best when provided K at 1.5 times the amount of N and cyclamen grows and develops best when provided K at twice the concentration of N. Most foliage plants develop best when provided 1.5 times as much N as K.

Form of Element

The form in which an element is provided can have a significant impact on plant growth. Plants primarily take up N as either ammonium (NH4+) or nitrate (NO3-). However, plants respond differently to the two forms of N and plants can store NO3- much more readily than NH4+. High NO3- fertilizer formulations generally produce stockier and shorter plants compared to high NH4+ sources. This has an impact the ratios of these two forms of N that greenhouse managers may choose to provide to a crop. For example, many plug producers prefer a water-soluble fertilizer which is nearly all NO3- nitrogen in order to promote the development of short, stocky and strong plugs.

In addition to the effect that the form of N can have on plant growth, the form of N provided can have a significant impact on substrate pH over time (as discussed previously under "Nitrogen") and this in turn can have a significant impact on plant growth. As mentioned above, the form of nitrogen can alter the substrate pH while residing there as well as a result of plant uptake.

While some plants thrive when provided N from sources high in NH4+ nitrogen (i.e. azalea), most floriculture species grow and develop best when most of the N is provided as NO3- with not more than 30% of the total N coming from NH4+ (or urea).

As discussed above, chelated micronutrients offer advantages in many scenarios versus sulfated micronutrients. In high pH, highly oxidized, or conditions such as very high salt concentrations, sulfated microelements can become relatively unavailable for plant uptake. Therefore, chelated forms may be more desirable.

There are various chelating agents available. While it is generally accepted that chelated nutrients are more stable than sulfated salts, pH can still have an impact the stability of the cation-chelate bond. For greenhouse crops production, EDTA (ethylenediamine tetraacetic acid) is a common chelate used in water-soluble fertilizers. Iron-EDTA can also be used as a supplemental source of Fe, but EDTA is less effective at maintaining the bond with Fe (or other cations) at moderate to high substrate pH. Even though Fe-EDTA has a higher percentage of Fe compared to other chelated Fe sources, it does not deliver the Fe to the plant as effectively as other chelated Fe sources. DTPA (diethylene triamine penta acid) and EDDHA [ethylenediamenedi (∝-hydoxyphenylacetic acid)] have a lower Fe content but are more stable at higher pH values making them more efficient at delivering Fe to the plant under high pH conditions. In order of effectiveness at delivering iron at high pH are EDDHA, DTPA and EDTA (most effective to least effective).

Substrate Components

Substrate components dramatically affect the chemical properties of the substrate. Some components such as perlite are generally considered chemically inert and do not have a major impact on the pH, E.C. or mineral nutrient content of the substrate. Other substrate components may contribute significant mineral nutrients. For example, coconut coir may have significant levels of K and rice hulls typically contain K, Ca, Si and Mn that can become available for plant uptake. Vermiculite may contain significant amounts of K and Mg and possibly Na. Composted manures can also contain significant levels of K and micronutrients and if added to the substrate they may provide enough micronutrients to meet the crop's need. In some cases, a substrate component may contain toxic levels of one or more mineral elements that limit its use (i.e. shredded rubber tires can contain toxic levels of zinc).

Components such as perlite and sand have a negligible cation-exchange capacity and are thus poorly buffered. Others such as composted manures, composted bark and peat moss have significant cation-exchange-capacities and are more highly buffered. The importance of the substrate cation-exchange capacity is discussed in more detail below.

The substrate pH will be significantly affected by the components used to formulate the substrate. Sphagnum peat moss-based substrates must be amended with calcitic or dolomitic limestone before use to adjust the pH to an acceptable level. The calcitic limestone will not only increase pH but will provide Ca to the crop. Dolomitic limestone will provide Ca and Mg. On the other hand, a coir-based substrate does not need to be amended with limestone for pH adjustment. Therefore, the limestone source of calcium is absent and must be provided though some other means (i.e. by adding calcium sulfate to the mix or providing all the required Ca in the liquid fertilization program).

The effect of the substrate components on pH, E.C. and cation-exchange-capacity and the substrate components contribution to mineral nutrients must be considered when designing a fertilization program.

Substrate pH

The pH of the substrate affects the availability of mineral elements. Under low pH, some elements especially cations such as Fe, Mn, Cu, and Zn become more available for uptake by plants. In fact, under prolonged low pH conditions these nutrients are prone to leaching due to their solubility in the acidic conditions which may eventually lead to plant nutrient deficiencies. If leaching doesn’t occur, then the high degree of solubility of these micronutrients may lead to excessive uptake by the plant and result in phytotoxicity. This phenomenon is common when geraniums and marigolds are grown in a low pH substrate (pH < 5.5), which often results in Fe-Mn toxicity.

Under high pH, even if elements are present in the substrate in the correct concentrations and proportions, they may be unavailable for uptake by the plant and therefore the plant may suffer from pH-induced mineral nutrient deficiencies (this is common for many micronutrients such as Fe, Cu and Zn). Iron deficiency is often a classic example of this situation. The substrate pH may affect the availability of other mineral nutrients differently. For example, Mo generally becomes more available as pH increases and is less available for uptake by the plant at a low pH.

The effect that pH has on the availability of mineral elements in the substrate is one reason why the recommended pH is in the range of about 5.5 to 6.5. At this pH, there is adequate availability of all mineral nutrients but with limited potential for pH-induced toxicities.

Not only does the pH of the substrate impact the fertilization program by affecting the availability of mineral nutrients, but the fertilization program can affect the pH of the substrate. As discussed previously, the use of fertilizers high in NH4+ nitrogen (NH4NO3, urea, etc.) tends to cause pH to decrease over time (and could cause pH to decrease to undesirable levels). Continued use of fertilizers high in NO3- nitrogen [Ca(NO3)2, KNO3, etc.] sources tends to cause the pH to go up over time with continued use (and the pH may increase to undesirable levels).

Premixed commercial fertilizers are composed of various fertilizer salts, and these salts may provide nitrogen as either NH4+ (or urea), NO3- or as a mixture of the forms. The ratio in which the two forms of N are provided will determine if the premixed fertilizer is acidic (causes pH to go down over time) or basic (causes pH to increase over time). The higher the ratio of NH4+ (and urea) to NO3-, the higher the potential acidity of the fertilizer. The higher the ratio of NO3- to NH4+, the higher the potential basicity.

The higher the potential acidity of a fertilizer, the greater the potential decrease in pH over time and the higher the potential basicity, the greater the potential increase in pH over time. The table below lists some examples of common fertilizer salts, premixed fertilizers and their potential acidity or potential basicity. It is useful to know the potential acidity or basicity of a fertilizer because it allows the greenhouse manager to understand how the use of the fertilizer will affect substrate pH over time.

| Potential Acidity and Basicity of Select Fertilizer Salts and Commercial Fertilizers | ||

Fertilizer |

Potential Acidityz |

Potential Basicityy |

Ammonium sulfate |

2,200 |

|

Urea |

1,680 |

|

Diammonium phosphate |

1,400 |

|

Ammonium nitrate |

1,220 |

|

Monoammonium phosphate |

1,120 |

|

Calcium nitrate |

|

400 |

Potassium nitrate |

|

520 |

Sodium nitrate |

|

580 |

15-5-15 Cal-Mag |

|

135 |

15-0-15 |

|

319 |

13-2-13 |

|

342 |

21-5-20 |

418 |

|

20-10-20 |

393 |

|

20-20-20 |

610 |

|

16-17-17 |

440 |

|

z Pounds of calcium carbonate required to neutralize the acidity of one ton of the listed fertilizer. |

y One ton of the specified fertilizer has the acid-neutralizing effect of the specified number of pounds of calcium carbonate. |

The effect that N form has on pH also provides a useful tool for greenhouse managers. As discussed under the "Irrigation" learning unit, carbonates and bicarbonates (and other bases) in the irrigation water will tend to cause the pH of the substrate to increase over time. If the level of carbonate and bicarbonate is very high (has a high alkalinity level), acid injection may be required to neutralize the carbonate and bicarbonate so that the pH does not increase to undesirable levels. However, if the irrigation water alkalinity level is not too high (or the crop time is short), fertilizer selection may be used as a tool for managing pH of the substrate. If the pH of the substrate begins to slowly increase (or if it is known that the pH will slowly increase over time), the greenhouse manager may choose to use a fertilizer that has a significant potential acidity. The use of such a fertilizer will tend to force the pH back down (offsetting the effect of the irrigation water). How much of an effect the fertilizer will have depends on how high is its potential acidity and how high is the irrigation water alkalinity. In contrast, if the pH of the substrate is lower than desired, a basic fertilizer may be used.

There are two primary problems with using fertilizer choice to control pH. The first is that the fertilizer requires time to cause a pH change and typically cannot be used to make major corrections in pH quickly. The second is that the crop being grown and the season may dictate if, and for how long, a type of fertilizer may be used. For example, a greenhouse manager may have an irrigation water source that has a moderately high alkalinity level. The use of acidic fertilizers may be able to offset some of the increase in pH caused by the water. However, especially during cooler months, continued use of the acidic fertilizers (high in NH4+ or urea) may not be possible since NH4+ could build up to phytotoxic concentrations in the substrate under cold conditions. In such a situation, a greenhouse manager might rotate between using a basic fertilizer for several irrigation cycles and an acidic fertilizer for several irrigation cycles. Therefore, although the selective use of fertilizers to control pH is a tool with some value, it is limited and the crop requirements must be kept in mind.

When substrate pH is either too high or too low and the pH must be adjusted quickly, there are several corrective procedures that may be employed. Two options for increasing pH are the use of a liquid lime product or using potassium bicarbonate. Liquid lime products are generally dolomitic limestone dissolved into water. Common applications rates are 2 to 4 quarts per 100 gallons of water. This will typically raise the pH by approximately 0.5 to 1.0 pH unit. This mixture will need to be kept agitated and can severely wear down injector parts if not diluted prior to use. This is often best applied by hand watering. Potassium bicarbonate also raises the substrate pH. The use rate is 1 to 2 pounds per 100 gallons of water. This solution is clear and easily passes through injectors, drip tubes, etc. However, a down side is that if the solution is splashed on foliage and not rinsed quickly, foliage burn is likely to occur. Also, be sure to follow up the next day with the application of a complete and balanced fertilizer as the system could be overwhelmed with potassium. Some growers with experience using both a liquid lime and potassium bicarbonate in combination will say that the liquid lime provides more residual control or a longer lasting pH increase.

For a fast acting pH decrease, iron sulfate may be applied to the substrate. Recommended rates will vary but most experts agree that 2 lbs/ 100 gallons of water is a good starting point. Similar to the potassium bicarbonate, the foliage should be rinsed after application to avoid burning. If insufficient pH drop occurs, apply the same iron sulfate solution rate again. It is better to take this approach and gradually adjust the pH versus using a very high dose initially.

Acid drenches can also be used to decrease pH quickly, but there is even a higher potential risk of plant damage as well to those handling the solution. Most common acids can be mixed with water to create a solution pH of about 2.0 which is used to drench substrate in containers. For sulfuric acid, experiment with adding 8 oz/100 gallons of water to see if that drops the water pH significantly. When choosing an acid consider that it is likely to supply additional nutrients (such as nitrogen, sulfur, or phosphorus) which may influence the overall nutrient balance.

Substrate Cation-Exchange-Capacity

The higher the cation-exchange capacity (C.E.C.) of the substrate, the greater its ability to retain cations. Since many of the mineral nutrients are cations, the greater the C.E.C., the greater the substrate’s nutrient-holding capacity. Mineral nutrients held by the substrate can be exchanged with the substrate solution (the liquid phase) and be available for uptake by the plant.

In greenhouse situations, when the mineral nutrients are provided as a continuous liquid feed, the C.E.C. is of less importance because mineral nutrients are supplied with each irrigation and do not need to be retained for future uptake by the plant (consider this dynamic as a hydroponic system). However, the C.E.C. can be important in constant liquid feed where microelements are only supplied at the being of the crop production or when plants are only fertilized periodically since the mineral nutrient cations need to be retained in the substrate rather than being leached out.

Cation-exchange capacity can also impact mineral nutrition through its role in substrate pH. Theoretically, the higher the C.E.C., the more resistant the substrate is to changes in pH. This is because the H+ in the substrate solution can be retained on the substrate surface in the same way that other cations are retained. Thus, the exchange sites on the substrate serve as a reservoir of H+ and remove or release H+ depending on H+ concentration in the substrate solution. This acts to help maintain a stable H+ concentration in the substrate solution and thus a stable pH. As previously discussed, the pH of the substrate impacts mineral nutrient availability. A substrate with a high C.E.C. will be less subject to pH changes and thus changes in mineral nutrient availability.

A common recommendation for increasing the C.E.C. of a peat-based substrate has been to add field soil (i.e. a loam) to the substrate. However, on a weight basis (per gram), peat has a higher C.E.C. than field soil. Therefore, it may not seem logical that adding field soil could increase the C.E.C. of a peat-based substrate. However, the reason is that on a weight basis, peat has a higher C.E.C. but on a volume basis field soil has a much higher C.E.C. This is because of the differences in bulk density between a field soil and peat. Field soil is much heavier. Therefore, a small volume of field soil will weigh much more than an equivalent volume of peat and the addition of a small volume of field soil (which relatively speaking weighs a lot) to a peat-based substrate will add a significant amount of C.E.C. to the substrate. Other components that may be added to a peat-based substrate to increase C.E.C. are vermiculite and calcined clay.

Finally, the more decomposed an organic material, generally the higher the C.E.C. This is one of the advantages of composting bark before using it in a substrate. In addition to removing the potential for nitrogen tie up, the partial decomposition that occurs during composting or aging increases the C.E.C. of the bark (see "Substrates" learning unit).

Electrical Conductivity

Electrical conductivity (E.C.) provides an overall estimate of the ions (i.e. Ca++, K+, NO3-, NH4+, etc.) in the substrate solution. However, it does not provide a measure of the concentration of any specific ion. If a complete liquid fertilization program is being conducted in which all macroelements and microelements are being provided in the appropriate proportions, E.C. can provide a good indication as to whether the overall fertility program is within an acceptable range. The acceptable range for E.C. varies with crop and crop stage (just as does fertility level). However, typically an E.C. of 2.0 - 3.0 mmho/cm is desirable for most actively growing crops based upon the SME (saturated media extract). Lower E.C. levels are desirable for seedlings and plugs and higher E.C. levels may be desired for crops requiring high fertility levels.

Electrical conductivities below desired levels in an indicator that the fertility level is below optimal and the fertilizer concentration being applied needs to be increased (or the frequency of fertilization increased). Electrical conductivities significantly above the desired level may be an indicator that fertility levels are too high in general or that one or more mineral nutrients are too high. If the E.C. is too high, a reduction in fertilization might be required, or if the E.C. is very high, clear-water leaching may be required. Keep in mind that the high E.C. values could be a result of a specific ion coming from the irrigation water such as sodium and may not be indicative of the “fertilizer” content of the substrate.

Electrical conductivity can also be used to monitor the fertilizer solution being applied to a crop. A given concentration of a fertilizer (or fertilizer salt) will have a specific E.C. This information is printed on most fertilizer labels. A sample of the fertilizer solution can be collected as it comes out of the hose, drip tube or emitter. The E.C. of the fertilizer-containing sample is determined. An E.C. of the water source is determined (without fertilizer). The E.C. of the water without fertilizer is subtracted from the E.C. of the fertilizer-containing solution. The resulting E.C. should be similar to the expected E.C. for the concentration of the fertilizer being used (see "Reading and Understanding Fertilizer Labels"). If the E.C. is not correct, either the amount of fertilizer used was incorrect or the injector was not working correctly.

Water Quality

Water quality impacts the nutritional program in two primary ways. First, the water may contain minerals (i.e. calcium, carbonates, borates, iron, sulfur, etc.) that may provide a portion of the mineral nutrient requirement of the crop. Water quality can also impact the pH of the substrate (see water quality under "Irrigation" learning unit). Through this mechanism, the water can affect the availability of mineral nutrients for uptake by the plant. For example, if a water with high alkalinity (high carbonate and bicarbonate content) is used (and no corrective measures such as acid injection are taken), the pH of the substrate will increase over time. As the pH of the substrate increases, many of the microelements (i.e. Fe, Cu, Zn) become less soluble and unavailable. As the pH continues to increase over time, microelements may become increasingly unavailable, and pH-induced microelement deficiencies may occur.

In turn a “pure” or water source with little to no alkalinity can also have an the adverse effect on the nutrition of a crop. When a water source has little or no alkalinity, the substrate pH tends to drop, especially if acidic fertilizers are being used. In this situation, the substrate components, limestone and fertilizer choice become more prominent in their effects on the substrate pH. As previously mentioned, where a very low alkalinity water source is being used and the pH tends to decrease over time, basic fertilizers may be used to manage pH.

Irrigation Method

Irrigation method affects fertility primarily by affecting the degree of leaching of mineral elements from the substrate. When overhead irrigating, the water flows through the substrate and drains from the container. As the water drains from the container, nutrients are leached from the substrate. If overhead irrigation is used and conducted in such a way as to minimize leaching, less loss of mineral nutrients occurs.

When trickle irrigation or drip tubes are used similar effects can be observed. But, since the water is delivered in a specific location channeling is often observed and the uniformity of the leachate may be less than that of traditional overhead water where the entire top of the substrate is irrigated.

If subirrigation is used, leaching, and thus loss of mineral elements does not occur to a significant extent. Additionally, salts tend to accumulate more readily in the top of the substrate due to evaporation. Most fertility recommendations have been developed assuming overhead irrigation with leaching. If subirrigation without leaching is conducted, recommended fertilization levels are often reduced by 30% to 50%.

When collecting substrate samples the irrigation method should be considered. As discussed, leaching and salt accumulation will vary based upon irrigation method. Therefore, where and how the substrate sample is collected will affect the testing results. For example, if a sample is collected by scraping the side of the entire substrate profile then a subirrigated plant will likely have a relative higher E.C. since salts naturally accumulate in high concentrations with this method. However, if the sample is collected by just selecting substrate from the middle or lower 2/3rd of the substrate profile then those high E.C. values might not be realized.

If collecting leachate samples by PourThru, the same considerations should be made. A key element of PourThru is that this method is simply displacing the substrate solution and that substrate solution primarily tends to reside in the lower 1/3rd of the container.